Why Trolley Wire Locomotives Are Ideal For Effective Mining Operations

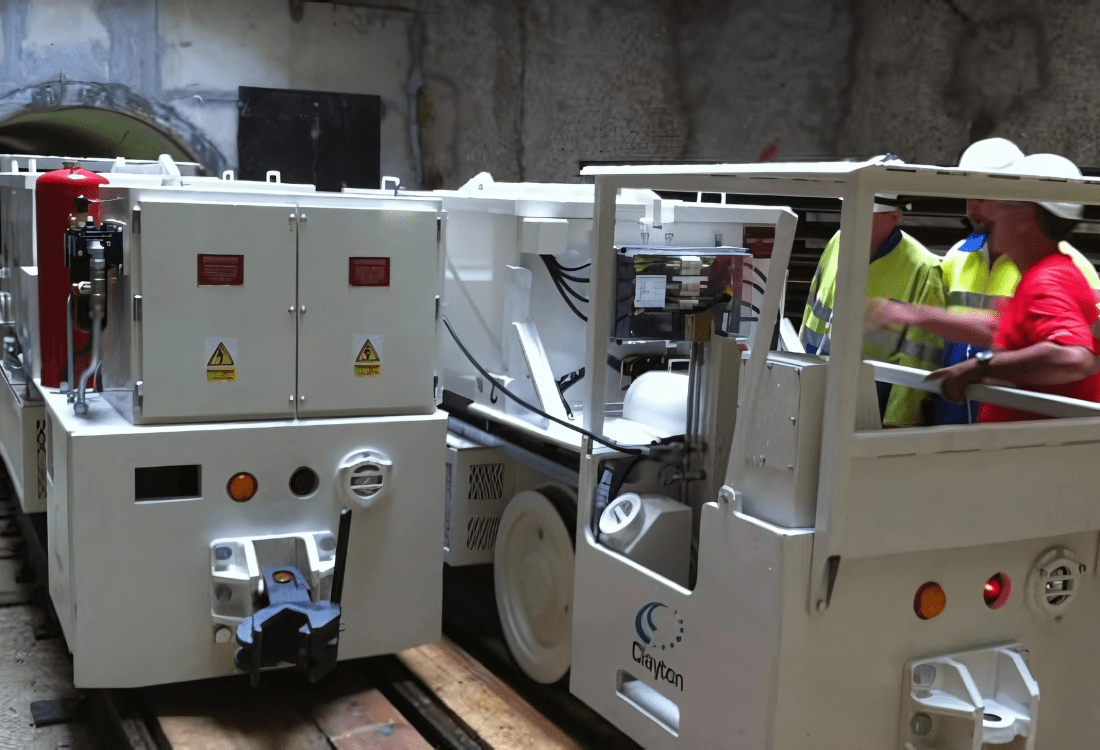

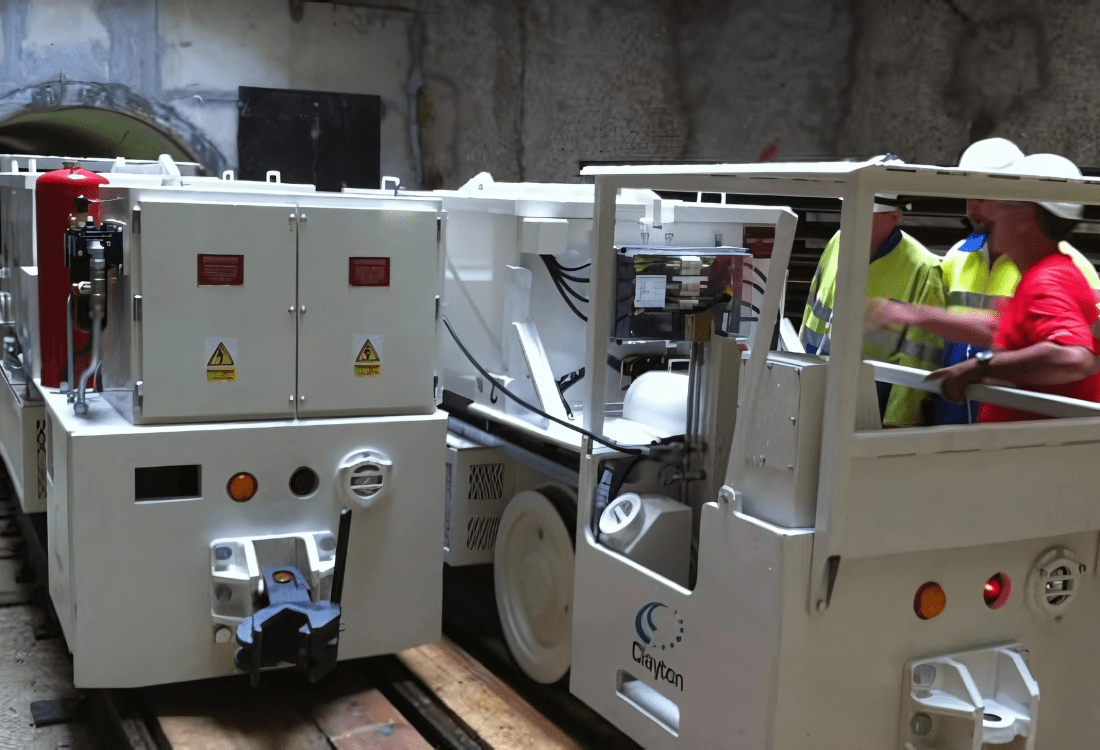

One of the primary challenges in any mining operation is efficiently transporting excavated materials. With harsh conditions, limited space, and the need for reliability, traditional diesel locomotives often fall short. This is where trolley wire locomotives shine as a go-to solution for mining operations. These locomotives utilise an overhead electrified cable system to transmit power, enabling safe, efficient, and flexible transport in challenging environments.

Trolley wire locomotives are powered by electricity transmitted through overhead wires. The electrical current is supplied by feeder stations placed at regular intervals along the track. The locomotive receives this power via a trolley pole, bow collector, or pantograph mounted on its top. A key component of the system is the automatic switch, which serves as the primary power switch for the main circuit. This switch provides critical overcurrent protection and allows operators to start and stop the locomotive safely and reliably.

Advantages Of Trolley Wire Locomotives In Mining Operations

The Impact Of Diesel Fumes

One of the most significant reasons to choose trolley wire locomotives over diesel-powered alternatives is the issue of diesel fumes. Diesel engines release exhaust gases that must be extracted from underground mines using large-scale ventilation systems. These systems are not only costly to install and operate but also add to the logistical complexity of mining operations.

While ventilation remains necessary for worker safety even with trolley wire locomotives, the absence of diesel fumes significantly reduces the burden on ventilation systems. This translates to lower operational costs and improved energy efficiency in maintaining air quality.

Diesel fumes also pose serious health risks to the workforce. Prolonged exposure to diesel exhaust can cause both short- and long-term health conditions, with evidence linking it to an increased risk of lung cancer. By eliminating diesel emissions, trolley wire locomotives contribute to a safer and healthier working environment for mining personnel.

Versatility

Trolley wire locomotives excel in both underground and surface mining operations. They provide reliable and powerful transport of materials and equipment, even in extreme conditions. Mining environments often feature high temperatures, humidity, and altitude variations, and trolley wire systems handle these challenges effectively. The compact overhead wire system also saves valuable space in tight underground tunnels where logistical constraints are common.

Flexibility

Modern trolley wire locomotives can seamlessly switch between power sources. This capability allows them to operate on both electrified and non-electrified tracks by combining overhead wire power with traction batteries. This dual-mode operation is essential for navigating areas where overhead wires cannot be installed or where additional power is needed for temporary tasks.

Advanced Technology

While trolley wire systems have been used for decades, modern locomotives incorporate cutting-edge technologies to improve efficiency and safety:

-

Remote Control and Automation : Many modern trolley wire locomotives are equipped with remote control or full automation capabilities, allowing for operation without an onboard driver. This not only enhances safety but also increases operational flexibility.

-

Optimised Efficiency : Advanced designs focus on reducing energy consumption and operational costs, helping mining operations maintain profitability while lowering emissions.

Environmental Benefits

As industries strive toward net-zero emissions, trolley wire locomotives offer significant environmental advantages. When operating on overhead power or battery, these locomotives produce zero emissions, contributing to reduced carbon footprints. This is particularly beneficial in confined or underground spaces, where diesel-powered locomotives pose health risks due to exhaust emissions. The electrified system also reduces reliance on fossil fuels, aligning with sustainability goals..

Multi-Application Design

Trolley wire systems are not confined to mining. They are also used in metro systems, mainline railways, and industrial depots, showcasing their adaptability and cost-effectiveness. For mining operators, this versatility ensures compatibility with other infrastructure or potential future applications.

Why Choose Trolley Wire Locomotives?

Trolley wire locomotives are a proven solution for overcoming the unique challenges of mining operations. Their ability to handle heavy loads, navigate confined spaces, and operate efficiently in diverse environments makes them an indispensable tool for modern mining. By integrating advanced technology, they offer improved safety, lower operational costs, and a sustainable alternative to traditional fuel-based systems.

Book a demo with the team at Clayton Equipment today and discover how our innovative solutions, such as modern trolley wire locomotives, can transform your business or get in touch!

Topics:

Mining Locomotives

- News (100)

- Battery Locomotives (35)

- Low Emission Rail (21)

- Mining Locomotives (10)

- Shunting Locomotives (10)

- Diesel Locomotives (9)

- LocoWatch (5)

- Sustainability (5)

- Locomotive (4)

- Battery Locomotives Battery Locomotives (3)

- IoT Telematics (3)

- 90 Years (2)

- Case Study (2)

- Haulage (2)

- Battery Shunter Locomotives (1)

- Clayton Equipment (1)

- Shunting Locomotives Shunting Locomotives (1)

- Switcher Locomotives (1)

- Telematics (1)

- September 2025 (2)

- August 2025 (2)

- July 2025 (3)

- June 2025 (4)

- May 2025 (1)

- April 2025 (2)

- February 2025 (1)

- January 2025 (1)

- September 2024 (1)

- August 2024 (2)

- July 2024 (2)

- June 2024 (2)

- May 2024 (1)

- April 2024 (1)

- March 2024 (1)

- February 2024 (1)

- January 2024 (4)

- November 2023 (1)

- September 2023 (1)

- August 2023 (2)

- July 2023 (2)

- June 2023 (2)

- May 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- November 2022 (2)

- October 2022 (1)

- August 2022 (1)

- July 2022 (4)

- June 2022 (1)

- May 2022 (1)

- April 2022 (2)

- March 2022 (3)

- February 2022 (8)

- January 2022 (1)

- November 2021 (3)

- October 2021 (1)

- September 2021 (3)

- August 2021 (7)

- July 2021 (7)

- June 2021 (7)

- April 2021 (1)

- January 2021 (1)

- December 2020 (2)

- August 2020 (1)

- March 2020 (4)

- February 2020 (3)

- January 2020 (4)

- December 2019 (1)

- November 2019 (2)

- October 2019 (3)

Subscribe by email

Share this

Previous story

← How Does A Diesel Electric Locomotive Work?You May Also Like

These Related Stories

Exhibiting - 66th Annual National Mine & Safety Conference, Philippines

Exhibiting - 66th Annual National Mine & Safety Conference, Philippines

November 1, 2019

1

min read

Future of Mining - The Electric Mine Conference

Future of Mining - The Electric Mine Conference

January 29, 2020

1

min read

How Battery Shunter Locomotives Enhance Worker Safety In Mining

How Battery Shunter Locomotives Enhance Worker Safety In Mining

July 23, 2025

2

min read

No Comments Yet

Let us know what you think