The Benefits Of Remote Condition-Based Monitoring For Locomotive Haulage

The locomotive industry is going through a transformative phase, driven in large part by the advent of new technologies including IoT telematics. In recent years, remote control locomotive operation and condition-based monitoring have emerged as game changers, providing real time insights into the health and performance of locomotives that are in use.

These data-driven solutions are allowing operators to enhance efficiency and improve safety, while also reducing maintenance costs at the same time. But just how is IoT telematics changing the way we use diesel electric locomotives? Let’s take a closer look.

How IoT Telematics Is Changing Maintenance

The traditional approach to locomotive maintenance has been to follow a schedule-based approach. This means that inspections and servicing is carried out at predetermined points. This method does ensure that all equipment is subject to a regular inspection and maintenance. However, it does not take into account the actual condition of the locomotive and may result in unnecessary servicing.

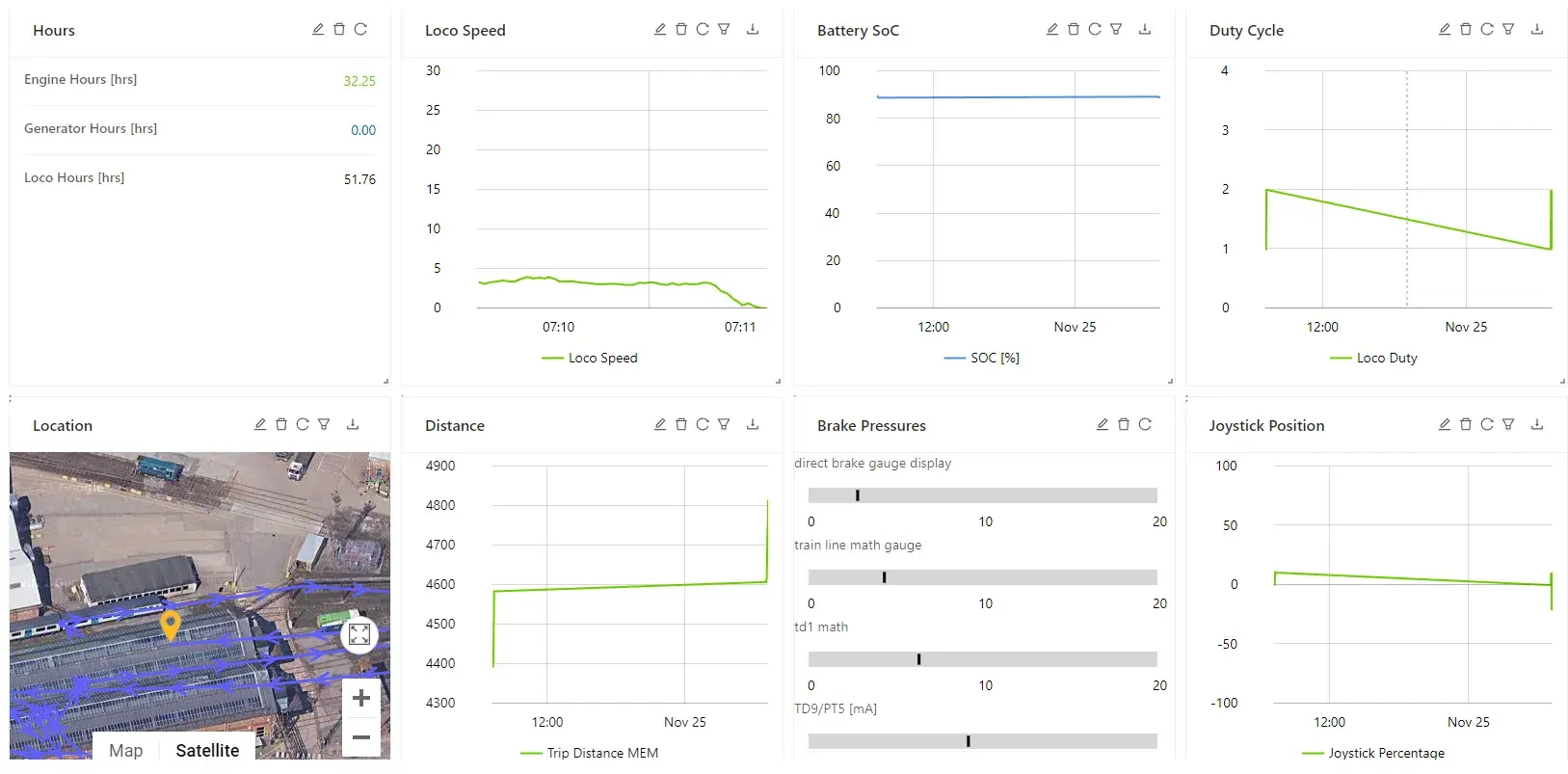

IoT telematics takes a different approach and enables condition-based maintenance based on information gained in real time from onboard sensors. This data provides a much clearer insight into the condition of the locomotive, detailing the performance of various factors, such as engine heath, fuel consumption, brake system status and more. This data and subsequent analysis allows for a shift from a reactive to a predictive maintenance system, addressing issues before they escalate and reducing the risk of unplanned breakdowns.

Reduced Downtime And Enhanced Performance

Breakdowns or prolonged maintenance can cause major issues with operations, leading to delays, financial losses and logistical disruptions. By switching to a remote condition-based approach you are able to mitigate the effects of downtime by detecting and dealing with system anomalies at an earlier stage. For example, if a sensor detects abnormal fluctuations in temperature or pressure inconsistencies, this could be a sign of a more serious issue and repairs can be scheduled. This will be less costly and avoid unplanned downtime. It also helps to maintain a better overall condition and enhance performance.

Cost Savings And Asset Maximisation

Maintenance expenses form a large part of any operating costs but with traditional schedule-based systems there can be a tendency for over-maintenance, when servicing is carried out when no issues exist. This all costs money in terms of labour, parts and downtime.

By using a condition-based system, repairs are only carried out when required, reducing the labour costs associated with inspections. This allows for a better use of locomotives, which can spend more time in operation, boosting return on investment.

Enhanced Safety

Safety is always a major priority and the early detection of safety issues is crucial for preventing accidents. Remote condition-based maintenance can help to ensure safer locomotives by spotting potential hazards before they become a more significant threat. As an example, brake system monitoring can alert operators to a decline in performance and real time diagnostics can detect any issues which may become more serious if not addressed.

Here at Clayton Equipment, our LocoWatch system integrates IoT telematics to ensure optimum performance and safety at all times. It provides real time monitoring and advanced diagnostics for better operational efficiency, enhanced sustainability and extended locomotive longevity.

Interested in IoT Telematics? Contact the Clayton Equipment team to learn more about how we incorporate our LocoWatch system into our locomotives. Speak to an expert today!

- News (101)

- Battery Locomotives (32)

- Low Emission Rail (21)

- Shunting Locomotives (10)

- Diesel Locomotives (9)

- Mining Locomotives (9)

- LocoWatch (4)

- Sustainability (4)

- Battery Locomotives Battery Locomotives (3)

- IoT Telematics (3)

- 90 Years (2)

- Case Study (2)

- Haulage (2)

- Locomotive (2)

- Clayton Equipment (1)

- Shunting Locomotives Shunting Locomotives (1)

- Switcher Locomotives (1)

- Telematics (1)

- July 2025 (1)

- June 2025 (4)

- May 2025 (1)

- April 2025 (2)

- February 2025 (1)

- January 2025 (1)

- September 2024 (1)

- August 2024 (2)

- July 2024 (2)

- June 2024 (2)

- May 2024 (1)

- April 2024 (1)

- March 2024 (1)

- February 2024 (1)

- January 2024 (4)

- November 2023 (1)

- September 2023 (1)

- August 2023 (2)

- July 2023 (2)

- June 2023 (2)

- May 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- November 2022 (2)

- October 2022 (1)

- August 2022 (1)

- July 2022 (4)

- June 2022 (1)

- May 2022 (1)

- April 2022 (2)

- March 2022 (3)

- February 2022 (8)

- January 2022 (1)

- November 2021 (3)

- October 2021 (1)

- September 2021 (3)

- August 2021 (7)

- July 2021 (7)

- June 2021 (7)

- April 2021 (1)

- January 2021 (1)

- December 2020 (2)

- August 2020 (1)

- March 2020 (4)

- February 2020 (3)

- January 2020 (4)

- December 2019 (1)

- November 2019 (2)

- October 2019 (3)

Subscribe by email

You May Also Like

These Related Stories

Harnessing The Future: The Advantages Of IoT Telematics

Clayton Equipment adds the benefits of IoT Telematics

No Comments Yet

Let us know what you think